Green sand cooler

The objective of a green sand foundry conditioning installation can be summarized in the following aspects:

- Reduce the temperature of the sand.

- Adjust the humidity level of the sand at the exit homogeneously.

- Separate the fines from the sand into two types (fine coarse by cyclone and impalpable by filter of sleeves) up to the client its subsequent reincorporation to the process.

- Raise the degree of “sponginess of the sand”.

In this way the sand acquires suitable properties to be reused thus a substantial improvement in the quality of the pieces is obtained reducing the number of defects in them.

The cooler is composed of the following elements:

- Suction enclosure.

- Water addition system.

- Flexible joint between fixed and mobile parts.

- Vibrating element with its own drivers

The installation has a control panel and cabinet for starting and stopping all the elements with their respective interlocks as well as for controlling the water addition in the equipment.

Suitable for conditioning sand return in green molding processes.

- Cooling from 120º C up to 40º C approximately.

- Humidity at the exit of 1.5% approx.

- Different driving systems on vibrating equipment such as vibrators, gearboxes or natural frequency devices.

- Screening system for the separation of particles prior to the entrance to the cooler.

- Standard series

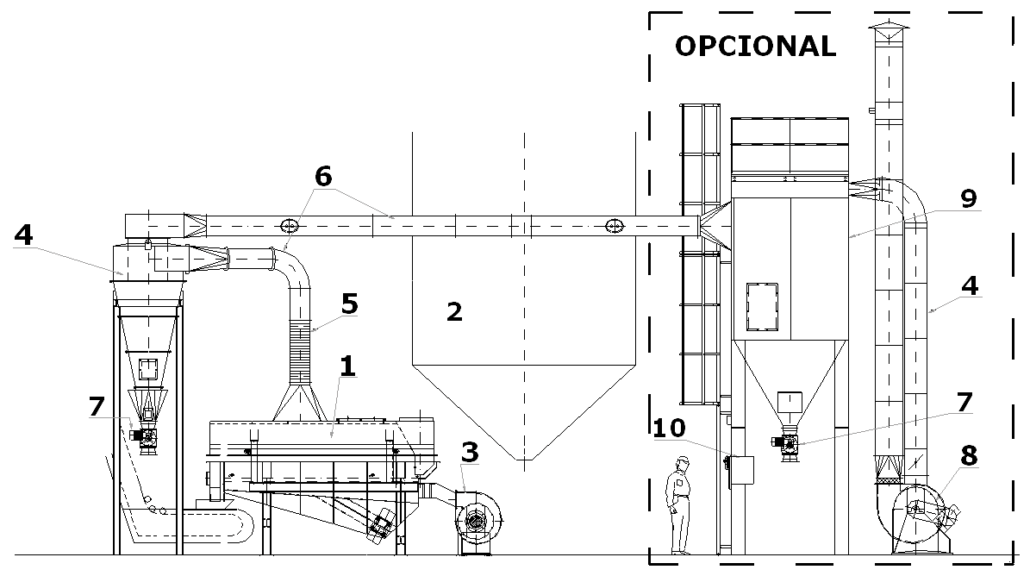

Elements of the installation

A sand conditioning installation is composed of these elements:

- Sand cooler

- Silo of sand

- Sand impulsion fan of room air

- Fines recovering cyclon

- Flexible tube

- Channels to interconnect the different elements

- Alveolar valves

- Suction fan of process air

- Sleeves filter

- Electro-valves sequencer box