FLIP FLOW SCREENS TYPE EMS

The EMS series or Flip Flow elastic mesh screens are designed to handle solid materials that are difficult to screen with conventional methods. Humidity, stickiness and shapes that tend to clog screens are some of the reasons for choosing this type of machine over conventional screening machines.

The equipment that can be configured with EMS series elastic mesh screens include electrical vibrators, eccentric shafts with adjustable masses or gearboxes.

Their operation is based on two independent frames that move the elastic mesh forcefully, thereby preventing the particles from snagging in the mesh.

Various configurations are available: single deck, dual elastic deck or a conventional mesh or perforated screen deck and a second elastic mesh deck.

Effect of the movement between frames in ESM screens

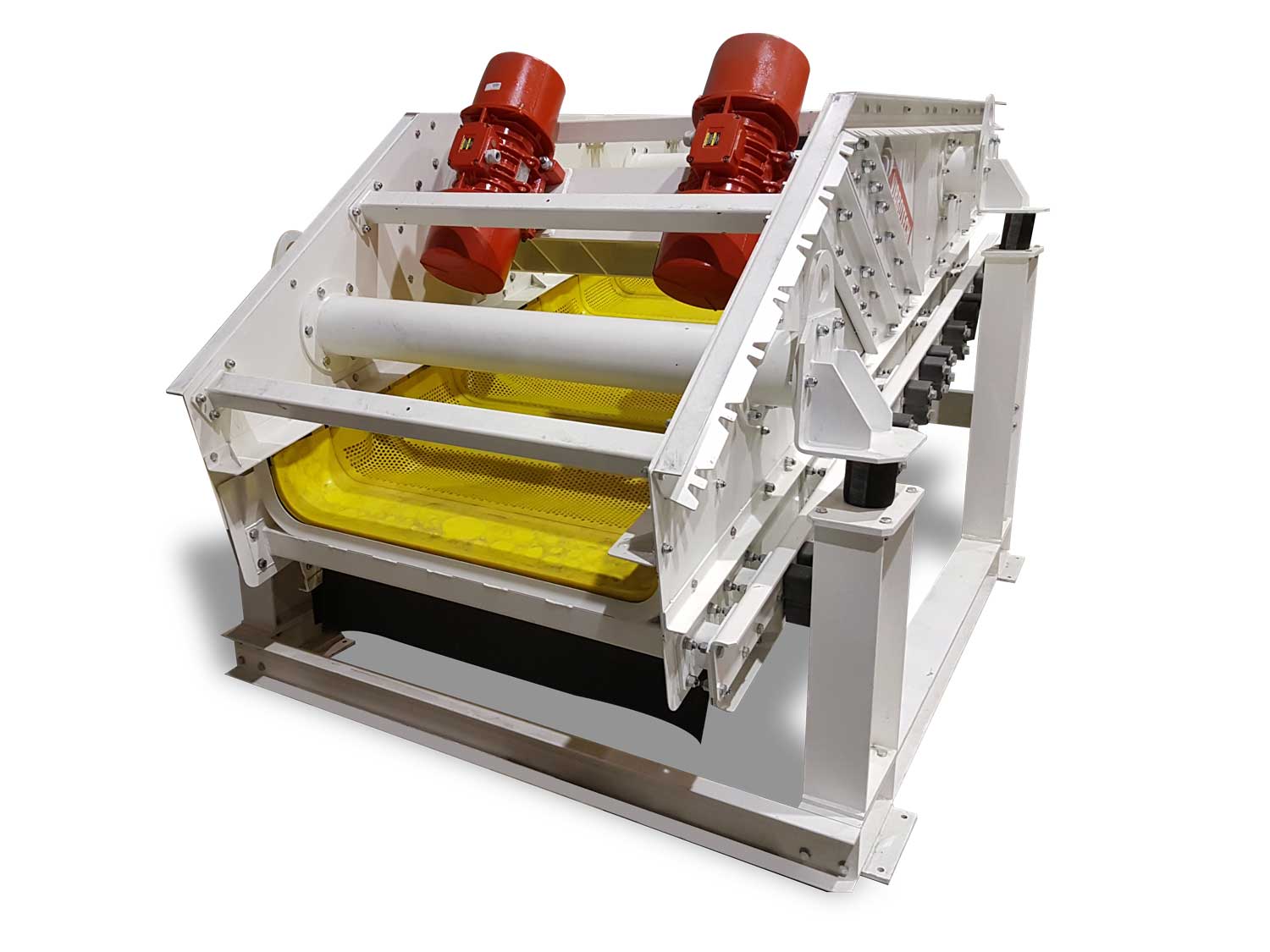

VIBROTECH elastic mesh screen model EMS 1200 x 3000 for tests

These machines are especially indicated for the following applications, among others:

- Screening humid products (compost, clay, etc.)

- Screening lightweight materials (light shredding machine waste, wood chips, etc.).

- Screening products that tend to stick or get snagged (the materials mentioned above and any other material that tends to clog other separation systems due to their shape or humidity).

- Screening highly abrasive products with fine edges (e.g., silica sand).

In all these cases, these types of machines offer advantages versus other market solutions (conventional screens, drum screens or disc screens):

- High screening efficiency.

- Installed power is normally lower than the power required by other machines (star screens, finger screens, drum screens, etc.) and their mechanical yield is greater, due to direct transmission via a cardan shaft.

- Screen maintenance is very easy, requiring only “bearing greasing”, without the need for auxiliary cleaning systems or stops due to maintenance or clogging. In addition, complete replacement of the meshes can be carried out in 1-2 hours.

- Due to their length, these types of screens can be installed in more compact spaces, lowering civil engineering costs (m3 of concrete required, smaller bay and roof dimensions, easier electrical installation, etc.).